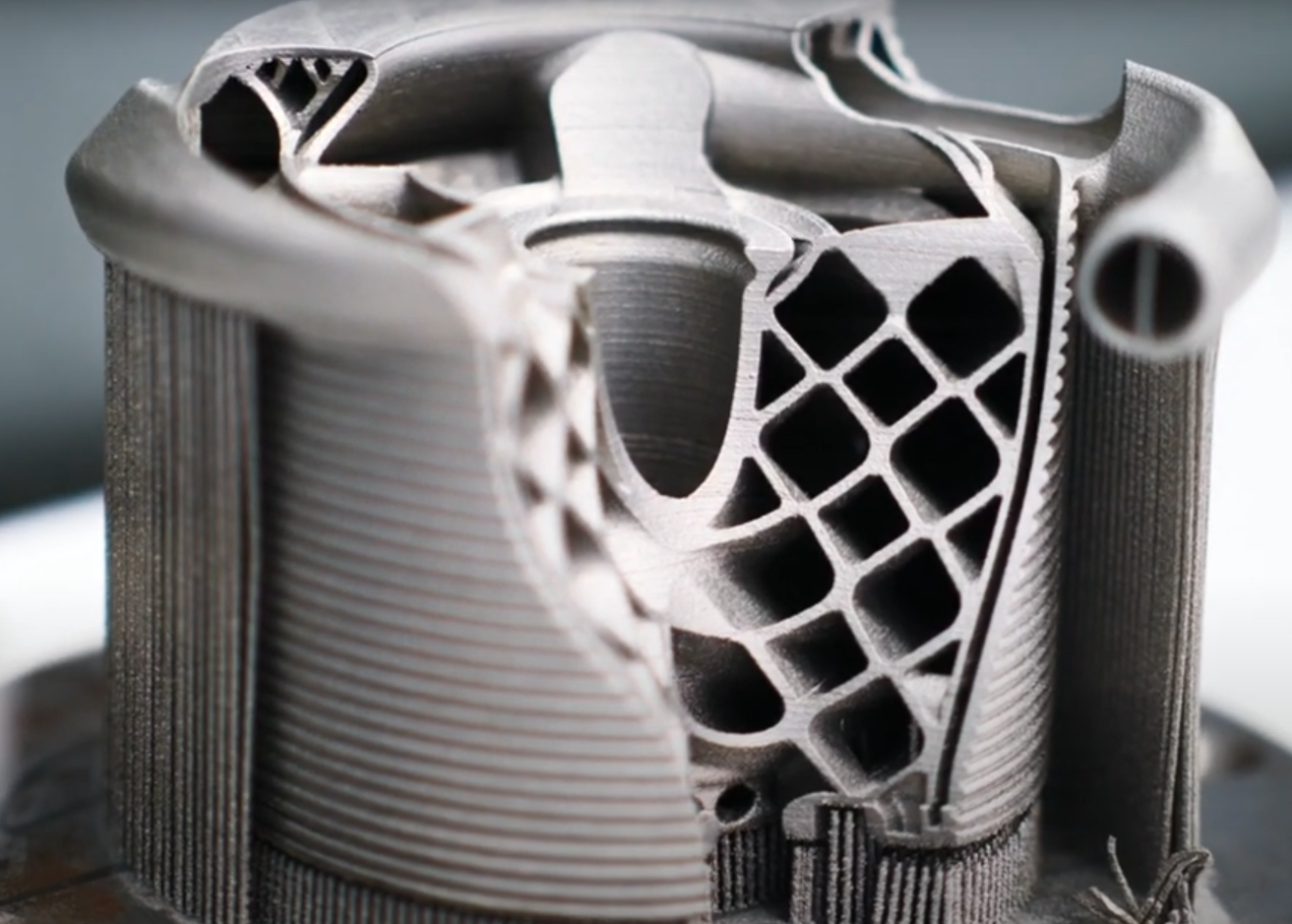

ADDITIVE MANUFACTURING

Go to the formEquipment description

At the IRIS Navarra Hub we offer companies, professionals, public entities and citizens a comprehensive additive printing service, aimed at facilitating the design, development and manufacture of parts and products using state-of-the-art 3D technologies.

This service allows to accurately create functional prototypes, final parts or customised models, reducing development times and costs.

It is provided with specialised technical support, adapted training and access to different printing processes and advanced materials. Thus, innovation, sustainability and the democratisation of access to digital manufacturing are promoted.

Equipment keys

- Industrial companies: Production of resistant polymer parts without the need for supports.

- Start-ups and entrepreneurs:High-precision development of functional prototypes and final products.

- Technological centres and universities:: Research in selective laser sintering (SLS).

- Research and development: Experimenting with new materials and design optimisation.

The cost depends on:

- Time of use of the equipment.

- Materials consumed (nylon powders and other thermoplastics).

- Maintenance and post-processing costs.

- Available rates: per hour, per project and per volume of material used.

This consists of booking a full manufacturing batch. Recommended for cases where priority, exclusivity in the use of the printing volume or specific configuration conditions are required. The user assumes the full cost of the job, which may include one or several own parts.

Designed for those who need to manufacture one or a few parts, this option allows you to share a job workspace with other compatible requests. In this way, the use of resources is optimised and the cost for each user is reduced. Job planning will be carried out by the technical team to guarantee its viability.

Reserved for more complex or prolonged processes, this option gives continuous access to the equipment within a defined framework. It is ideal for iterative developments, prototype series or functional validations. It includes technical support and allows managing multiple manufacturing phases in a single project.

Infograph

Download this small infograph with the keys and most important aspects of the four equipment units that make up the additive printing service:

- Additive printing Form 4

- Additive printing Formlabs FUSE 1

- Additive printing INTAMSYS FUNMAT 610HT

- Additive printing samylabs alba 300

Maintenance and revision of the equipment

Yes, it has regular maintenance and technical reviews to ensure its optimal operation.

What if there are problems?

The DINABIDE technical team is in charge of maintenance and repair. Users should follow the usage protocols to avoid damage.

Do I need training to use this equipment?

Yes, training is mandatory.

- Estimated duration: 4 to 16 hours, depending on the level of use.

FUNDED BY: